The Milling

Our flours are 100% natural, without enzymes or chemical agents. The first sign of this quality is the fragrance that the flour releases since the kneading.

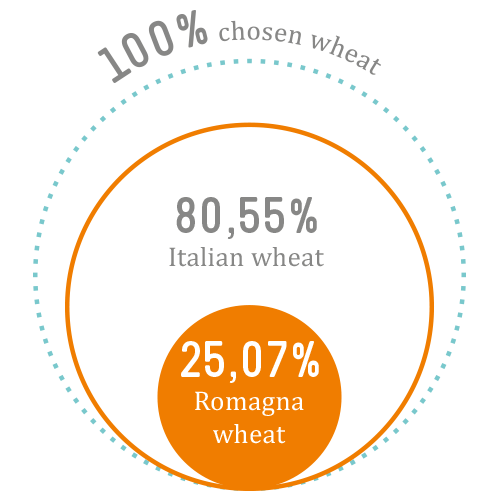

We choose the finest wheat, almost exclusively Italian, rigorously NO GMO: for every kind of wheat we look for the best plantation areas. Since 2002, for a higher protection, our company concludes supply chain contracts certificated UNI EN ISO 22005 with farms in our region. Because not every ground is the same.

We developed more than 60 references, starting from real milling recipes, every one designed listening to the professionals’ needs: bakers, pizza masters, pastry chefs, piadina and pasta makers, cooks and food factories, with whom we discussed in order to satisfy their needs.

For the storage of wheat and flour we adopted a technology that enables us to ensure a constant quality for every flour. The flour you will be using tomorrow will have the same rheological and processing characteristics of the one you are using today.

Our flours are guaranteed from the most important food certifications, but the one that makes us prouder is the BRC Food Safety 8. In our branch, this is the highest achievable level of certification of the whole productive process and we obtained it in 2019 in both our plants: Faenza and Marzeno.

Italica 100% grani italiani Line and Le Farine del Passatore

The brand Italica® 100% grani italiani was born from the love of our country; this label was designed for all our flours that derive from the exclusive milling of Italian wheat.

The brand Le Farine del Passatore® was born from our desire to forge solid relationships with our region. This line concerns zero-mile Romagna flours with certification of controlled supply chain UNI EN ISO 22005.

For us, sustainability is a daily commitment and it is the key to build a future of general well-being.

The excellence of Molino Naldoni flours

The wheat and the produced flours are analysed in the lab daily. Microbiological analysis, filth tests and research about the presence of pesticides, mycotoxins and heavy metals are carried out periodically.

Thanks to an efficient system of storage and logistics, Molino Naldoni keeps the final product in conditions of maximum hygiene even during the last and delicate step of the transport.

Based on the client’s demand, for every lot of the product, the Certificates of the rhelogical parameters are released.